BLOGS

What is head pressure HVAC is a question that often comes up when an HVAC system struggles to cool properly, runs inefficiently, or shuts down unexpectedly. Head pressure is a critical measurement inside an HVAC system that directly affects performance, energy use, and system safety. When head pressure is too high or too low, it places extra stress on major components and can shorten the lifespan of the AC unit.

Understanding what head pressure HVAC means helps homeowners recognize why certain cooling problems occur and why professional diagnosis is often required. This guide explains head pressure in simple terms, how it works, why it matters, and what signs may indicate a problem.

Head Pressure in HVAC

Head pressure in HVAC refers to the pressure level on the high side of the refrigeration cycle. It is measured at the discharge side of the compressor, where refrigerant leaves the compressor as a hot, high pressure gas.

Head pressure HVAC readings indicate how hard the system is working to move heat out of the home. Proper head pressure allows the system to release heat efficiently. When head pressure rises above normal levels, the system must work harder, which affects cooling performance and energy efficiency.

How Head Pressure Works in Your HVAC System

To understand head pressure, it helps to look at how an HVAC system moves heat. The refrigeration cycle relies on pressure differences to transfer heat from inside the home to the outside air.

In simple terms:

- Refrigerant absorbs heat inside the home

- The compressor raises refrigerant pressure and temperature

- Hot refrigerant travels through the discharge line

- Heat is released through the condenser

- Refrigerant pressure drops before repeating the cycle

Head pressure HVAC measurements reflect how effectively heat is being released. If heat cannot escape properly, pressure builds up on the high side of the system.

Why Head Pressure Matters for Performance and Efficiency

Head pressure directly impacts system efficiency and component health. When head pressure is within the proper range, the HVAC system runs smoothly and delivers consistent cooling.

Head pressure problems matter because they can:

- Reduce cooling efficiency

- Increase energy consumption

- Overheat the compressor

- Trigger system shutdowns

High head pressure forces the system to work harder, which leads to higher utility bills and increased wear on components.

Common Causes of High Head Pressure

High head pressure HVAC issues are usually caused by conditions that prevent heat from leaving the system efficiently. Several common problems can lead to elevated pressure.

Common causes include:

- Dirty or blocked condenser coils

- Restricted airflow around the outdoor unit

- Overcharged refrigerant levels

- Non functioning condenser fan

- Faulty fan cycle switch

When airflow is restricted or heat cannot dissipate, refrigerant pressure increases rapidly. This often results in high head pressure combined with abnormal suction pressure readings.

Signs You Might Have Head Pressure Problems

Head pressure problems often show warning signs before major damage occurs. Paying attention to these symptoms can help prevent costly repairs.

Common signs include:

- AC unit shutting off unexpectedly

- Reduced cooling output

- Hot air blowing from vents

- Unusual noises from the system

- Higher than normal energy bills

In many cases, high head pressure occurs alongside high suction pressure, indicating an imbalance in system operation.

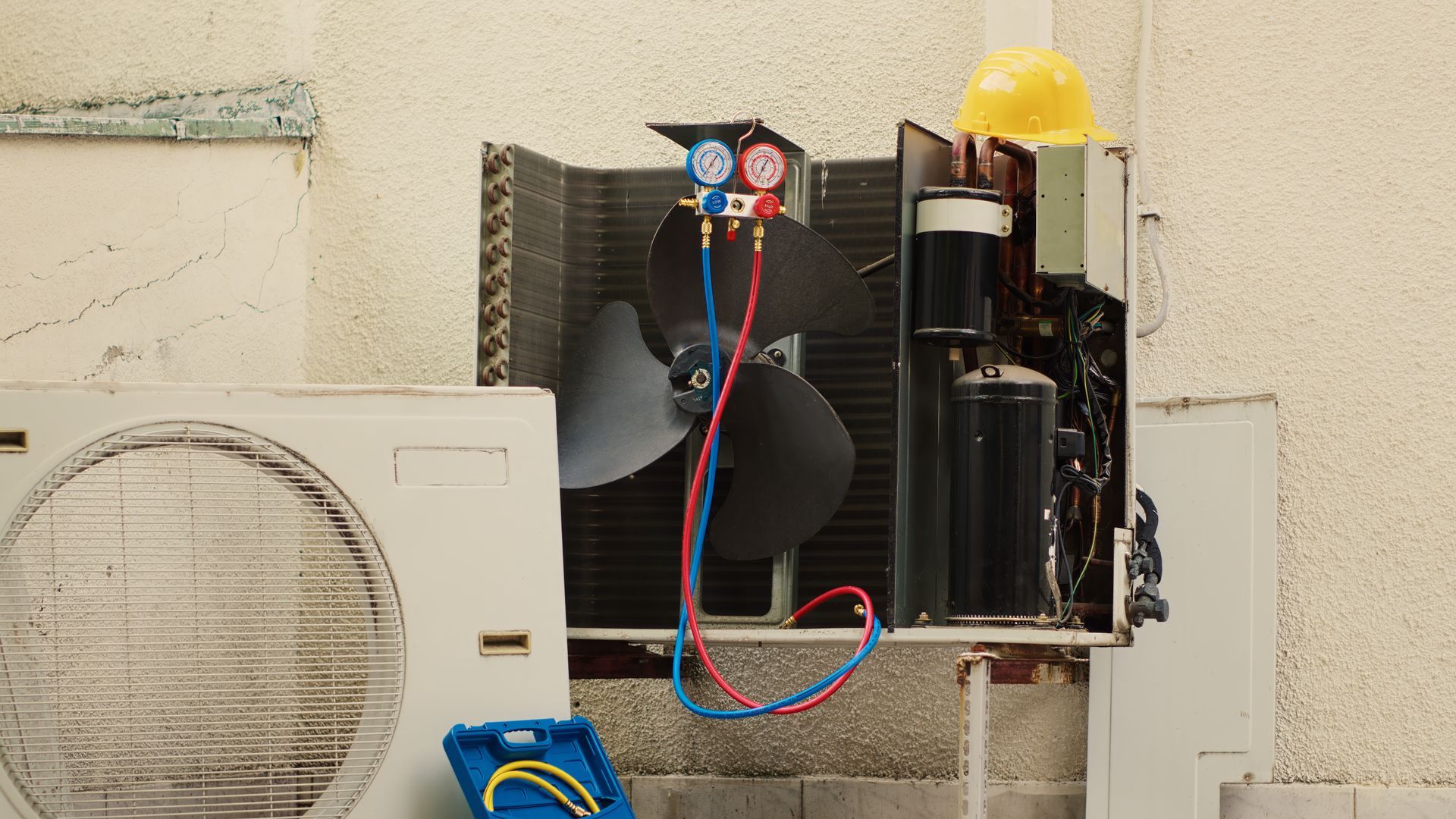

How to Check and Measure Head Pressure

Measuring head pressure requires specialized tools and technical knowledge. It is typically done by trained technicians using pressure gauges connected to the system.

During measurement, technicians evaluate:

- Head pressure readings

- Suction pressure levels

- Discharge line temperature

- Overall system performance

Because incorrect measurements or adjustments can cause damage, homeowners should avoid attempting to check head pressure themselves. Issues related to head pressure HVAC conditions are best handled through professional HVAC Repair services.

Simple Fixes and Preventive Measures

While head pressure issues often require professional service, some preventive steps can reduce the risk of problems developing.

Helpful preventive measures include:

- Keeping outdoor units clear of debris

- Replacing air filters regularly

- Ensuring proper airflow around the system

- Scheduling routine inspections

Regular HVAC Maintenance helps identify airflow restrictions, dirty coils, and early signs of pressure imbalance before they escalate.

The Role of Airflow in Head Pressure Control

Airflow plays a major role in regulating head pressure. When airflow across the condenser is restricted, heat cannot escape efficiently.

Airflow problems may result from:

- Dirty condenser coils

- Blocked outdoor units

- Failing condenser fans

- Clogged air filters

Maintaining clean air filters and clear airflow pathways supports stable head pressure and efficient system operation.

High Head Pressure vs Low Head Pressure

While high head pressure is more common, low head pressure can also cause performance issues. Both conditions indicate imbalance within the system.

High head pressure usually results from heat rejection problems, while low head pressure may be caused by:

- Low refrigerant charge

- Cold outdoor temperatures

- Metering device issues

Proper diagnosis is essential because symptoms can overlap, and incorrect adjustments may worsen the issue.

Why Head Pressure Issues Should Not Be Ignored

Ignoring head pressure HVAC problems can lead to serious damage. Compressors are especially vulnerable to prolonged high pressure conditions.

Potential consequences include:

- Compressor failure

- Refrigerant leaks

- Electrical component damage

- Complete system breakdown

Addressing pressure issues early reduces repair costs and protects system longevity.

How Regular Maintenance Helps Prevent Head Pressure Problems

Routine maintenance plays a key role in preventing head pressure issues. Regular inspections allow technicians to catch airflow restrictions and pressure irregularities early.

Maintenance helps by:

- Cleaning condenser coils

- Checking fan operation

- Inspecting refrigerant levels

- Verifying system pressure balance

Consistent HVAC Maintenance reduces the likelihood of sudden pressure related failures.

When to Call a Professional

Head pressure issues should always be evaluated by a qualified technician. Attempting DIY fixes can result in refrigerant loss, system damage, or safety risks.

Professional service is recommended when:

- The system shuts down repeatedly

- Cooling performance drops suddenly

- Pressure related warnings occur

Timely HVAC Repair ensures accurate diagnosis and safe correction of head pressure HVAC problems.

Conclusion

What is head pressure HVAC comes down to understanding how pressure controls heat movement within an HVAC system. Head pressure plays a vital role in system efficiency, safety, and performance. When pressure levels rise too high, cooling efficiency drops and component damage becomes more likely. Recognizing the causes, warning signs, and preventive steps helps homeowners protect their system. With proper airflow, regular maintenance, and professional service when needed, head pressure HVAC issues can be managed before they lead to costly repairs.

Frequently Asked Questions

What Does Head Pressure Mean in an Hvac System?

Head pressure refers to the pressure on the high side of the HVAC system where hot refrigerant exits the compressor.

What Can Cause High Head Pressure?

Dirty condenser coils, restricted airflow, refrigerant overcharge, and fan failures are common causes.

How Do I Know If My Hvac Has Head Pressure Issues?

Symptoms include system shutdowns, poor cooling, high energy bills, and unusual operating noises.

Is Head Pressure Something a Homeowner Can Fix?

No, head pressure issues require professional tools and expertise to diagnose and correct safely.

Can Head Pressure Be Too Low?

Yes, low head pressure can occur due to low refrigerant levels or cold conditions and can also affect performance.